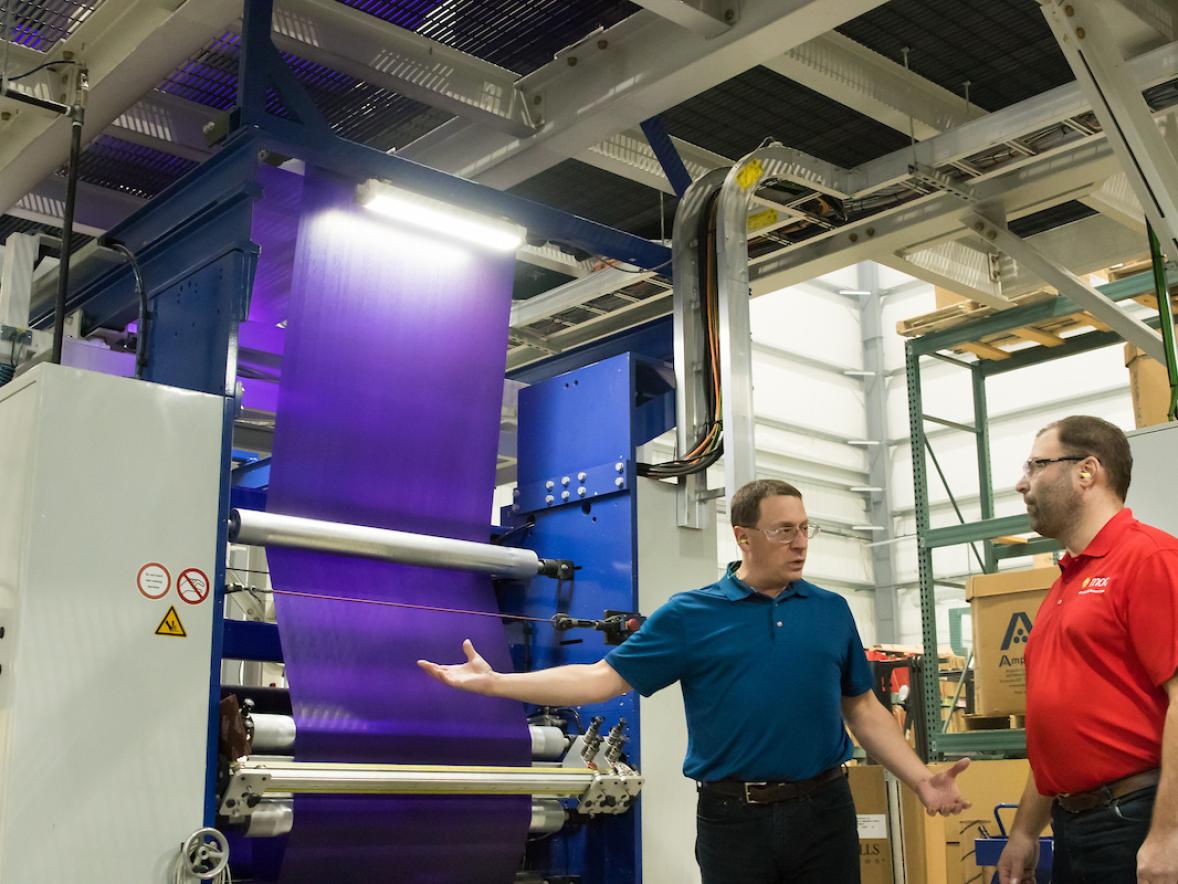

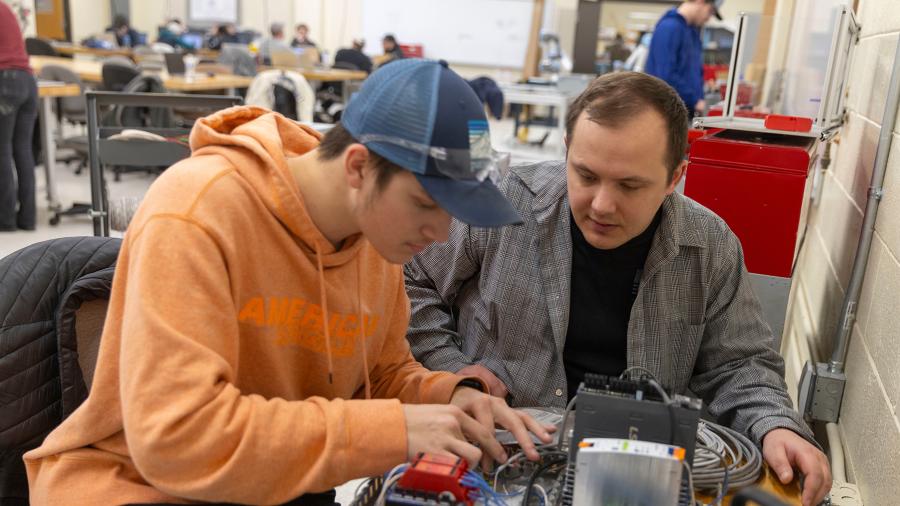

Students in the manufacturing, mechanical and computer and electrical engineering programs at UW-Stout are fully engaged in the lab-based — polytechnic — learning environment. It’s part of their bachelor’s degree experience from the get-go — doing more on day one.

When they reach Senior Design Experience courses, however, the applied learning focus goes up a notch. In yearlong projects, they are immersed in labs to solve a complex problem. The challenge isn’t just theoretical, either: It helps a sponsoring company move forward with answers to specific needs with design solutions.

With the end of the academic year just six weeks away, the seniors are bearing down on the solutions. Twelve projects from the fall are entering their final build stages, and 12 new projects are in the design phase this semester.

Participating companies include Viracon, Loos Machine and Automation, St. Croix Tactical, Graco, nVent, Fastenal, Diasorin, Industrial Heat Transfer, Rassbach Museum, Colder Products Company, Antigo Zeon, and two San Francisco-based companies — Gaeastar and Mantle.

In recent years, other companies working with students have included Andersen, OEM Fabricators, Proem, Curt Manufacturing, Advanced Molding Technologies, Advantek and Arconic.

Sponsoring companies provide full financial support of all needed equipment and materials for the testing of ideas and build of final products or systems. The projects range in scope from product designs to fully integrated system designs.

“An experience like this puts us in the realm of where we need to be as we prepare for our careers,” said Sophie Gelhar, of Green Bay, a senior double-majoring in mechanical engineering and in applied science.

Research, design, develop, present

Gelhar’s team is working on a better way to safely and efficiently move 200-pound boxes from a tilt table onto a cart for a manufacturer in Owatonna, Minn. As with many projects, their research began by visiting the company’s production facility to see the current process.

After initial research, teams developed solutions, proved concepts and completed their designs to finish out their first semester. Then, they presented their design solutions using charts, graphs, diagrams, matrixes, videos and more.

Company sponsors, professors and fellow classmates looked on. Stressful though it was, the students embraced the challenge. Their presentations drew questions from the professors and executives, sending them back to the lab, comparable to the engineering process that they will experience daily when their careers begin.

“The true value of our Senior Design Experience is to allow developing engineers to practice the stage gate-driven design and project build,” said Assistant Professor Dan Bee, noting a methodology that includes built-in reviews. “Our students know how to design and build their projects.”

The course blends all three of the university’s tenets — applied learning and research, business and industry collaboration, and career-focused experiences.

Instrumentation Coordinator Paul Craig said the experience prepares students for a smooth transition into the workforce. “They begin their careers with a leg up on other engineering graduates because of the extensive laboratory-based instruction, which our polytechnic university is known for,” Craig said.

Graduates from the mechanical and manufacturing engineering programs in 2022-23 reported 100% employment and an average starting salary of more than $70,000, according to a new university First Destination Report.

Along with mechanical and manufacturing engineering, UW-Stout’s Robert F. Cervenka School of Engineering has programs in plastics engineering; and computer and electrical engineering, as well as a bachelor’s program in engineering technology.

A master’s in manufacturing engineering is available on campus or online.

###