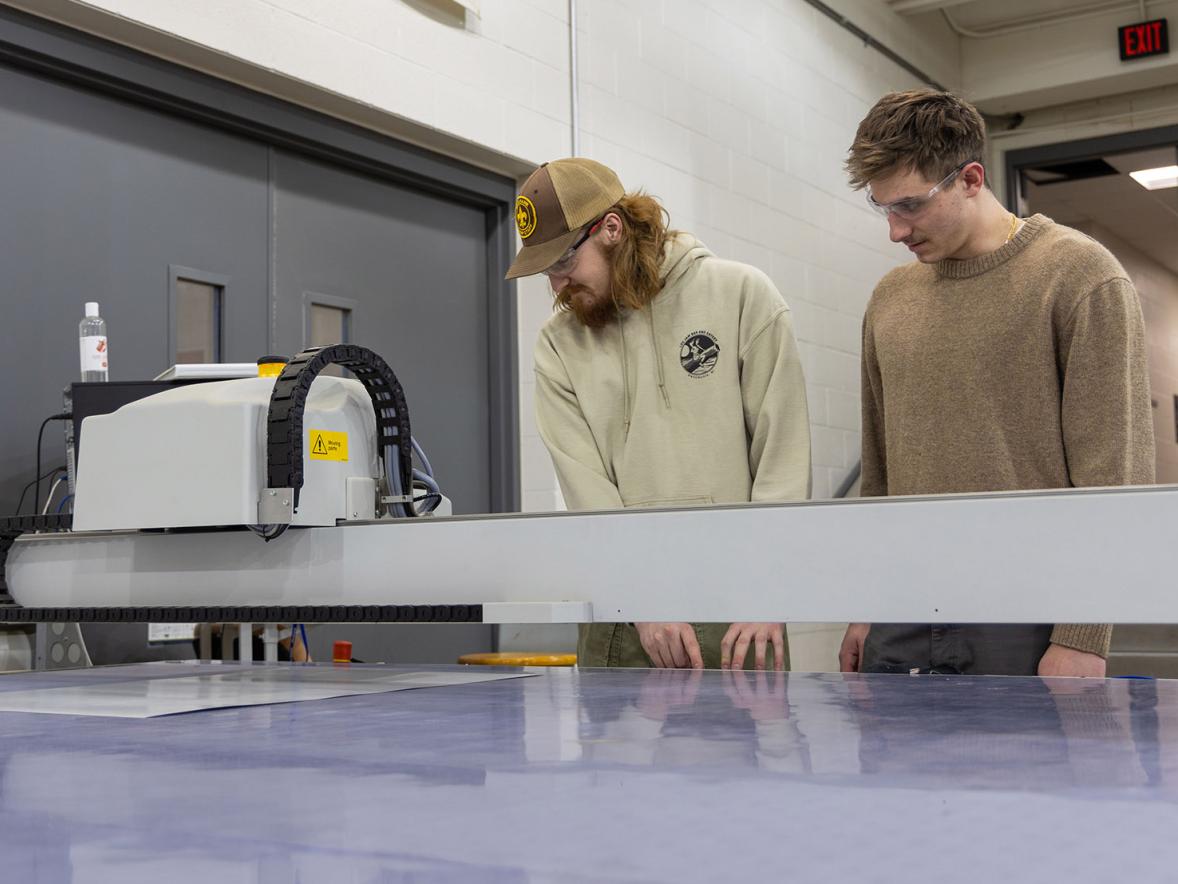

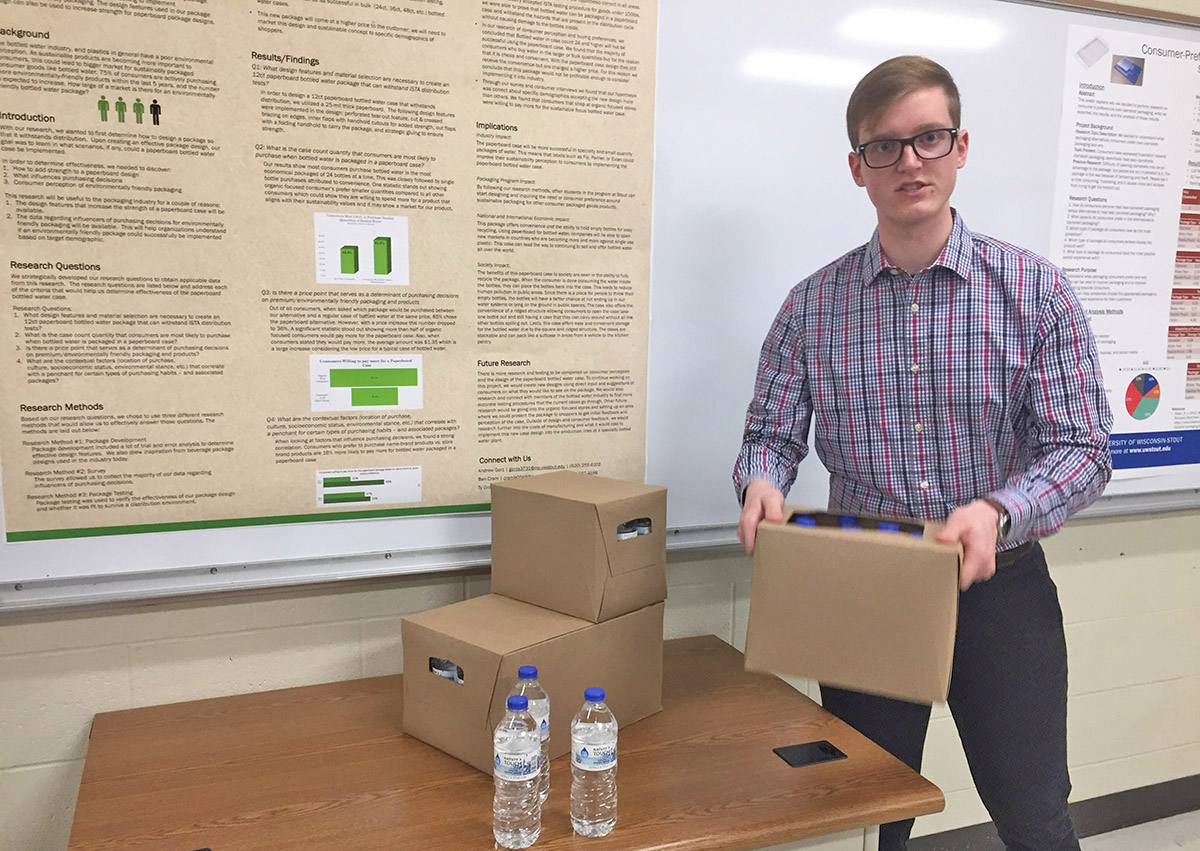

A paperboard case for bottled water instead of plastic shrink wrap seems to appeal to upscale customers and would be more sustainable, according to research by University of Wisconsin-Stout senior packaging students.

“You can take a bottle out and still have the strong package to hold the other bottles,” said Ben Cram, who graduated Dec. 14. “The package also provides a place to store the empty bottles, and the bottles and packaging can all be recycled.”

Cram, of Lakeville, Minn., will work at Buddy’s Kitchen in Lakeville beginning in January as a packaging engineer. Buddy’s Kitchen makes breakfast sandwiches for airlines and convenience stores.

In their research, Cram and seniors Ty Grovogel and Andrew Gorz, both of Algoma, determined that for 24-packs and larger of water the plastic wrap worked better and was more economical.

“(Paperboard packaging) would be for a more specialty market or a premier brand, or consumers willing to pay more for sustainable packaging,” Cram said.

The students presented their research at the end of the semester in Fryklund Hall as part of their packaging Senior Research Seminar class taught by John Spartz, associate professor in English and philosophy.

Spartz has a technical communication and user experience background. He encourages students to think about the best methods to conduct their research, evaluate their findings and then share those findings clearly through various media.

“As an outsider to the packaging world, I am able to bring a fresh perspective and help students communicate their ideas to varied audiences,” Spartz said. “Asking students to engage in the systematic process of conducting primary, human-centered research — and then presenting their findings to a lay audience — provides them with opportunities to better understand the value of this work as nascent industry professionals.”

Paperboard a cut above

Paperboard also won out in research done by two other students, who graduated Dec. 14. Samantha Spahr, or Oakwood, Minn., and Joey Griese, of Hudson, surveyed consumers to find out if they preferred paperboard cartons, flexible pouches, blister packs or clamshell packaging.

“The most positive experience was with paperboard boxes,” Spahr said. “The opening experience was the best; they are recyclable and were viewed as the best by consumers.”

However, when consumers wanted to see the product they were buying and the assurance that the product was safe from theft, clamshell was preferred.

“A lot of people aren’t aware clamshell packaging can be recycled,” Griese said. “We would encourage companies to use cartons when they can because it is preferred by the consumer, or they should look in the future to improve clamshells’ ease of opening but still keep the visibility and antitheft protection.”

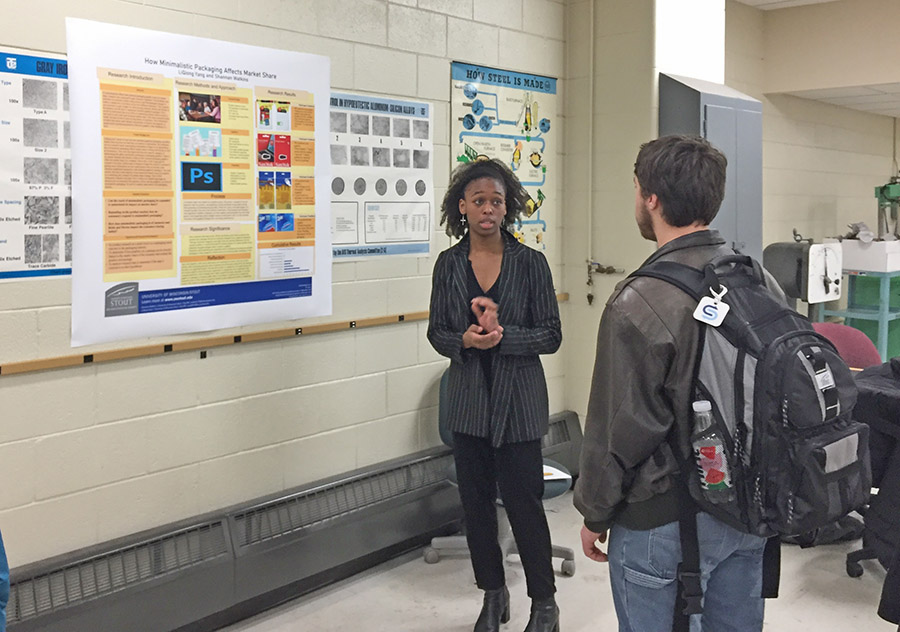

Shannan Watkins, a senior from Hoover, Ala., who graduated Dec. 14, and LiQiong Yang, a senior from Menomonie, researched minimalistic graphics and their effect on market share. They specifically looked at the apparel, electronics, household goods and the pet industries in traditional brick and mortar retail stores. Fewer graphics save ink, require less printing time and save money and resources.

They found consumers prefer more graphics on packaging. “I was surprised,” Watkins said. “At heart, I am a minimalist. I was hoping that would be the case with our research.”

Ben Crooks, a senior from River Falls, and Emily McCormick, of Eau Claire, who graduated Dec. 14, searched the use of molded pulp dunnage instead of Styrofoam.

Pulp dunnage, which usually comes from recycled paper content, can handle 35 pounds of weight and up to 60 g-force. It is popular with consumers because it is easily recycled. However, Styrofoam can handle more weight and force but isn’t easily recycled.

McCormick saw some companies using Styrofoam and others using pulp to protect items. She had a Cooperative Education position through Career Services at Ten-E, a hazardous material testing facility in Newport, Minn., from summer 2016 to January 2017.

As a sustainability minor, McCormick wants to work with companies to help them gain in the sustainability market. “I expected molded pulp to be the be-all to end all,” she said. “But we figured out through research, even for lighter items, it may not be the answer.”

UW-Stout is one of only a few schools in the U.S. and the only school in the UW System that offers a bachelor’s degree in packaging.

###

Photos

UW-Stout packaging student Ben Cram talks about a paperboard case for bottled water that appeals to upscale customers for its sustainability over plastic shrink wrap. /UW-Stout photos by Pam Powers

Packaging student Shannan Watkins talks about research she did on packaging graphics.