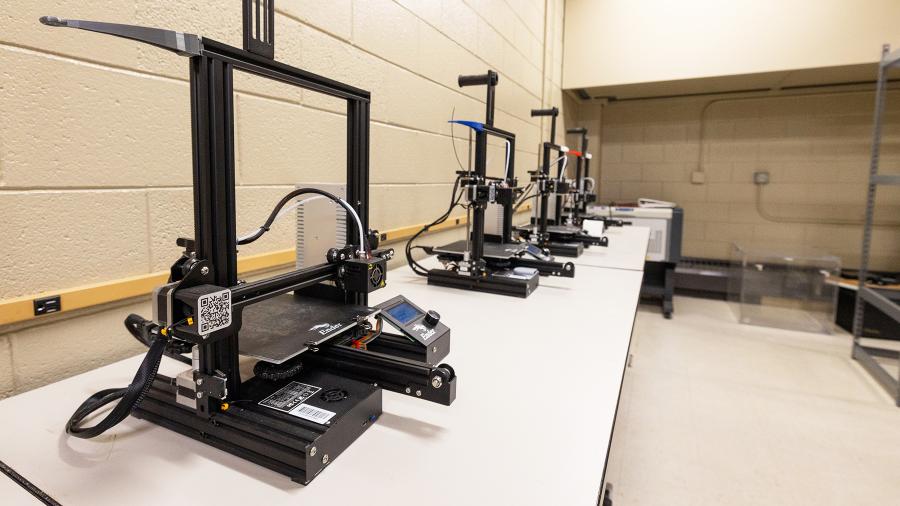

Empowering Engineering Solutions Through 3D Printing

At UW-Stout, our Additive Manufacturing Lab supports all our engineering programs by providing the cutting-edge 3D printing technology to model and print parts and prototypes that address professional challenges. Featuring a range of advanced 3D printers, including Stratasys, Markforged, and Prusa models, this lab enables students to enhance their skills in 3D modeling, material selection, and the printing process—from design to prototype—as they develop the ingenuity and expertise to tackle modern engineering challenges with confidence.

Dive Deeper Into the Additive Manufacturing Lab's Equipment

The OneClick MPRINT Metal Printer delivers fast, precise, and affordable professional-grade metal additive manufacturing products. Capable of producing complex prototypes, functional parts, and custom components in a single streamlined workflow, the MPRINT Metal Printer is widely used across aerospace, automotive, and advanced manufacturing sectors. Engineering students can use the MPRINT to design, test, and refine real-world parts, gaining hands-on experience with cutting-edge fabrication tools that prepare them for careers in innovative, technology-driven companies.

- Process: Laser fuses 20–80 μm layers of metal powder.

- Materials: 316 stainless steel; can also print tool steels, copper, titanium, aluminum.

- Build Volume: 150 × 150 × 150 mm

- Tolerance: ~0.1 mm (geometry dependent)

- Resolution: 0.5 mm

Built for industrial production, the Stratasys Fortus 450MC Printer is capable of printing large, production-grade parts in aerospace thermoplastics with unmatched strength, accuracy, and repeatability. Manufacturers deploy it for tooling, fixtures, jigs, and end-use components that survive heat, load, and time. Defined by rugged FDM performance, it stands apart from the Origin II’s photopolymers, the H350’s powder fusion, and the J55’s color realism. From aerospace and automotive to healthcare, energy, and education, the Fortus 450MC empowers teams to validate designs faster, customize at scale, and turn bold concepts into reliable, industry-shaping innovations across demanding environments worldwide with confidence and speed every single day.

- Use: Large-format industrial thermoplastic printing for jigs, fixtures, prototypes, and end-use parts.

- Materials: ABS, ASA, carbon-filled nylon, PC/ABS, polycarbonate, TPU, ULTEM, Antero; specialty properties available.

- Build Volume: 406 × 355 × 406 mm

- Tolerance: 0.127 mm

- Resolution: 0.8 mm

Imagine bringing production-quality resin parts to life with speed, precision, and scalability—the Stratasys Origin II Printer makes it possible. Powered by programmable photopolymerization, it delivers exceptional surface finish, isotropic strength, and repeatable accuracy for end-use components. Industry leaders use the Origin II for manufacturing housings, connectors, and consumer products at scale. Unlike the Fortus 450MC’s thermoplastic FDM strength, the H350’s powder fusion, or the J55’s color-focused realism, the Origin II excels in high-throughput resin production. From medical and consumer goods to electronics and industrial design, it enables organizations to iterate faster, customize efficiently, and redefine how innovation reaches the market.

- Process: P3 Digital Light Processing for photopolymer resins; fast, production-quality parts.

- Applications: Prototypes, tooling, high-volume small parts.

- Materials: Wide range of engineered resins (flexible, high-temp, flame-retardant, strong).

- Build Volume: 192 × 108 × 370 mm

- Tolerance: 0.05–0.10 mm

- Resolution: 38.5 μm pixel; 25–200 μm layer height

Unlock a new level of industrial freedom with the Stratasys H350 Printer, a production-scale powder fusion system built for consistency, throughput, and design flexibility. Using Selective Absorption Fusion™, it produces strong, isotropic nylon parts without supports, enabling dense nesting and cost-efficient batch manufacturing. Manufacturers rely on the H350 for end-use components, housings, clips, and ducting across automotive, consumer goods, and industrial sectors. Distinguished from the Fortus 450MC’s FDM strength, the Origin II’s resin precision, and the J55’s visual realism, the H350 empowers industries to scale customization, streamline supply chains, and innovate boldly with durable, production-ready parts.

- Process: SAF powder-bed fusion for Nylon (PA 12); production-grade parts.

- Speed: Full build in ~12 hours.

- Build Volume: 315 × 208 × 293 mm

- Tolerance: 0.300 mm

- Resolution: 0.100 mm

- Surface Roughness: ~8 μm

Color, texture, and realism converge in the Stratasys J55 Printer, a compact PolyJet printer that transforms ideas into vivid, multi-material prototypes overnight. Designers and engineers use it to validate form, fit, ergonomics, and branding with transparent, flexible, and full-color parts in a single build. Unlike the Fortus 450MC’s strength-first FDM, the Origin II’s production resins, or the H350’s powder fusion efficiency, the J55 excels at visual storytelling and rapid decision-making. From product design and healthcare to architecture, consumer goods, and education, it accelerates feedback, aligns teams, and inspires innovation through instantly understandable, lifelike models that spark confidence, clarity, and momentum everywhere.

- Process: Full-color PolyJet printing; photorealistic prototypes and medical models.

- Build Volume: Round tray, 1,174 cm² area, 190 mm height

- Tolerance: 0.150 mm (up to 100 mm)

- Resolution: 0.018 mm

Engineers, designers, and innovators rely on the Markforged Mark II Printer for strong, accurate parts using continuous carbon fiber reinforcement and advanced thermoplastics. From tooling and jigs to end-use components, the Mark II has become a trusted tool for workflows in aerospace, automotive, and industrial manufacturing. Using the Mark II will help you gain real experience with materials and design strategies used in today’s top innovation companies and build confidence in solving complex fabrication challenges.

The Formlabs Form 4 SLA Printer delivers professional-grade resin 3D printing with exceptional accuracy, faster print speeds, and automated calibration, which sets it apart from the Form 2. Capable of fine-detail prototypes, functional parts, and complex assemblies, the Form 4 is used across medical, engineering, and industrial design fields.

The Formlabs Form 2 SLA Printer remains a reliable, high-resolution resin 3D printer capable of producing detailed prototypes, intricate models, and functional parts used across engineering, product design, and healthcare sectors. Even with the availability of the newer Form 4, the Form 2's proven performance, extensive material library, and accessibility keep it relevant for use in labs and classrooms. By mastering the Form 2, you'll gain hands-on skills in precision fabrication, rapid iteration, and problem-solving.

The Bambu Lab H2C delivers a powerful combination of speed, efficiency, and professional‑grade capability by using a Vortek Hotend Change System to virtually eliminate purge waste and dramatically reduce multi‑color print times. This system assigns each filament one of seven dedicated hotends, allowing smooth, waste‑free transitions between materials and enabling up to seven materials simultaneously with capacity up to 24 filaments with the automatic material storage units. Inductive heating technology rapidly brings nozzles to temperature in about eight seconds, while a high‑torque PMSM servo extruder boosts extrusion stability and enables real‑time detection of clogs or grinding for more reliable high‑flow printing. The actively heated chamber supports environmental temperatures up to 65 C for demanding engineering filaments with reduced warping, and a suite of smart automation features which reduces technician intervention and enhances overall print consistency.

Powerful, precise, and built for advanced workflows, the Bambu Labs H2D Pro Printer prints large, high-temperature engineering parts with dual nozzles, an active heated chamber, HEPA filtration, and blistering toolhead speeds—supporting engineering plastics and specialty filaments. Favored over the X1E, X1 Carbon, A1 and A1 Mini for its dual-extrusion, higher temperature range, and pro connectivity, it’s used for prototyping, tooling, and small-batch production. College students validate designs, test materials, and practice production-ready workflows confidently.

The Bambu Lab X1E Printer stands out as a professional-grade CoreXY 3D printer built for high-performance engineering use. The X1E offers active chamber heating, up to 320 °C extrusion, robust air filtration, AI failure detection, and enterprise-ready connectivity not found on other Bambu models like the H2D Pro, X1 Carbon, A1, or A1 Mini. Industry teams use the X1E for advanced prototyping, tooling, and specialized parts.

A high-performance printer built for rapid iteration, advanced materials, and dependable automation, the Bambu Labs X1 Carbon Printer offers capabilities far beyond the A1 and A1 Mini and makes an ideal choice over the H2D Pro and X1E when dual extrusion or enterprise networking aren’t required. This is a great printer to help you gain experience optimizing designs, managing fast development cycles, and delivering industry-ready results.

The Bambu Labs A1 Printer delivers fast, accurate, full-size printing with smart calibration, multi-color capability, and effortless setup—ideal when speed, accessibility, and reliability matter more than industrial extremes. Chosen over the H2D Pro, X1E, and X1 Carbon for its simplicity and value, and over the A1 mini for its larger build volume, the A1 supports rapid prototyping, design validation, and production-ready thinking.

Big ideas don’t always need big machines. The Bambu Labs A1 Mini Printer packs speed, precision, and smart automation into a compact, affordable printer perfect for quick prototypes, fixtures, and concept models. It’s chosen over the H2D Pro, X1E, X1 Carbon, and A1 when agility, space, and rapid iteration matter most in early design cycles.

The Stratasys F170 3D Printer is part of the F123 series, renowned for its precision and reliability in producing high-quality parts using Fused Deposition Modeling (FDM) technology. This printer supports both prototyping and production applications, offering a range of material options and user-friendly software, making it an essential tool for engineering students to develop industry-relevant skills.

The Prusa i3 MK3S is a reliable and versatile open-source 3D printer. Known for its robust design and ease of use, this printer provides students with hands-on experience in 3D printing technology, including setup, calibration, and printing with various materials, fostering a practical understanding of additive manufacturing.

Industry Partner Access

The Additive Manufacturing Lab serves more than students. UW-Stout is proud to partner with innovative business and industry throughout the country to enhance emerging ideas, elevate research and development projects, and amplify productivity. Our Additive Manufacturing Lab is perfectly positioned to produce robust parts in a wide range of thermoplastics, photo-cured resins, and stainless steel for use in a wide variety of applications—from low-cost prototypes to final-use parts. Contact us today for a free, confidential consultation.