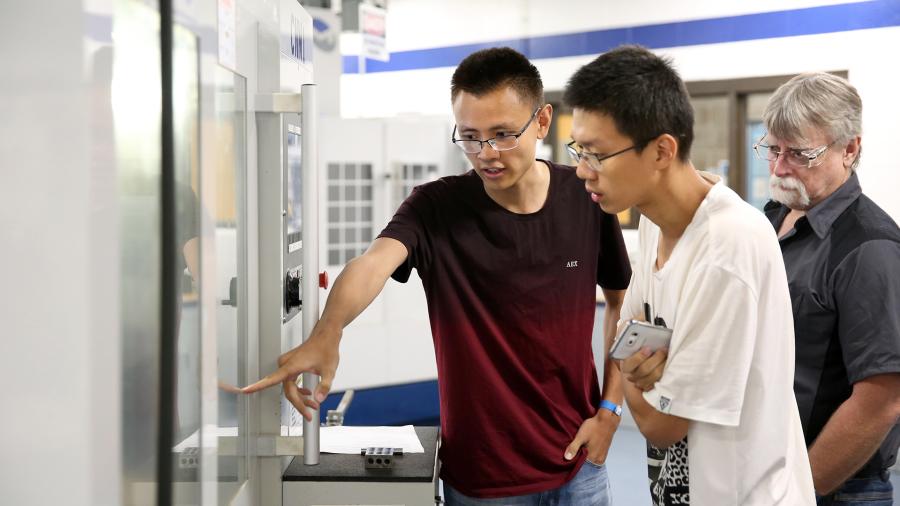

UW-Stout's Manufacturing, Material Removal & Metal Forming Lab is an industry-standard lab space where engineering students can apply hands-on learning from day one. Equipped with professional-grade machinery, including engine lathes, milling machines, and sheet metal equipment, this lab offers an immersive experience in metal forming and machining. Students actively engage in practical tasks that build real-world skills and deepen their understanding of mechanical engineering principles.

Degrees That Do More in This Lab

Dive Deeper Into the Manufacturing, Material Removal & Metal Forming Lab's Equipment

The Milltronics ML16 is a CNC lathe designed for precise turning operations on materials such as metal and plastic. It automates the turning process through computer-controlled programs, ensuring high accuracy and consistency, making it ideal for manufacturing components, prototyping, and custom part production.

CNC machines are automated devices that cut and shape materials like metal, plastic, and wood with high precision, performing tasks such as drilling, milling, and grinding. Controlled by computer programs, they ensure consistent and accurate production of components, making them essential in manufacturing, prototyping, and producing custom parts.

The Gearhead Lathe offers precision and versatility with a 5 HP motor and spindle speeds up to 3000 RPM. It features a high-quality Japanese bearing spindle, patented Meehanite castings, electronic variable speed control, and a Fagor two-axis digital readout, making it ideal for demanding metalworking projects.

The Milltronics VM20 is a vertical machining center used for milling operations on materials like metal and plastic. It automates milling tasks with computer-controlled precision, ensuring accurate and consistent production, making it suitable for manufacturing components, prototyping, and creating custom parts.